The New Ultimate Printing Plate Box Storage

A method that saves you time, money and protect your printing plates, but before we get ahead of ourselves a bit of key information might put all into perspective why we say this is the ultimate solution.

Over the last few months one of our sales and technical representative put in the hour revieing one of our customers packaging materials, processes and the possibility to improve with potential cost savings. During this period we have managed to reduce cost on the current solutions of majority of there packaging but there was one area that we and our customer spend some time for the best possible solution.

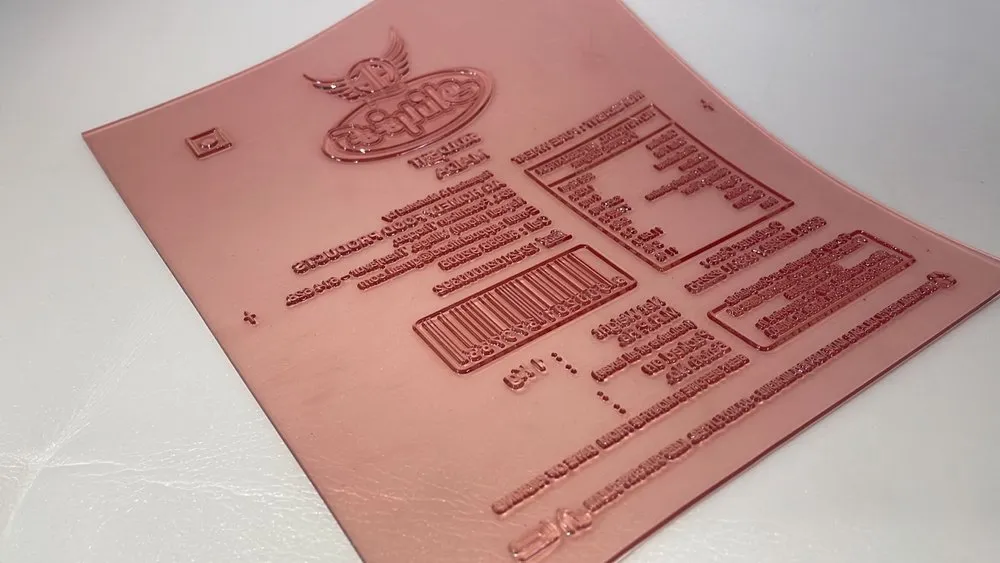

This was the method on how they store their printing plates, quick lesson for those who does not know what a printing plate is. Printing plates are used to transfer images and text onto the surface you want to print on. Whether it’s printed bags, magazines, catalogues or clothing, usually some form of printing plate or printing block is used.

But why was this a concern you might ask, to put it in simple terms it cost them money, the way the plates was stored caused damages, exposure to light, time consuming setup, long searching periods to name just a few. Let me explain a bit more printing plates can be expensive and has quite a few factors that drives that cost, such as complexity, sizes, colours, what machine it will run on. So using an average cost per plate of R 700.00 (South African Rand) we did some calculation based on the data our customer supplied us.

Over a period of 6 months they have had to replace 34 plates due to damages caused by the original storage solution, this brings a total of R 23 800.00 spend on plates they had to replace cost that is not budgeted for necessary, if we take this over a one year period a total spend of R 47 600.00.

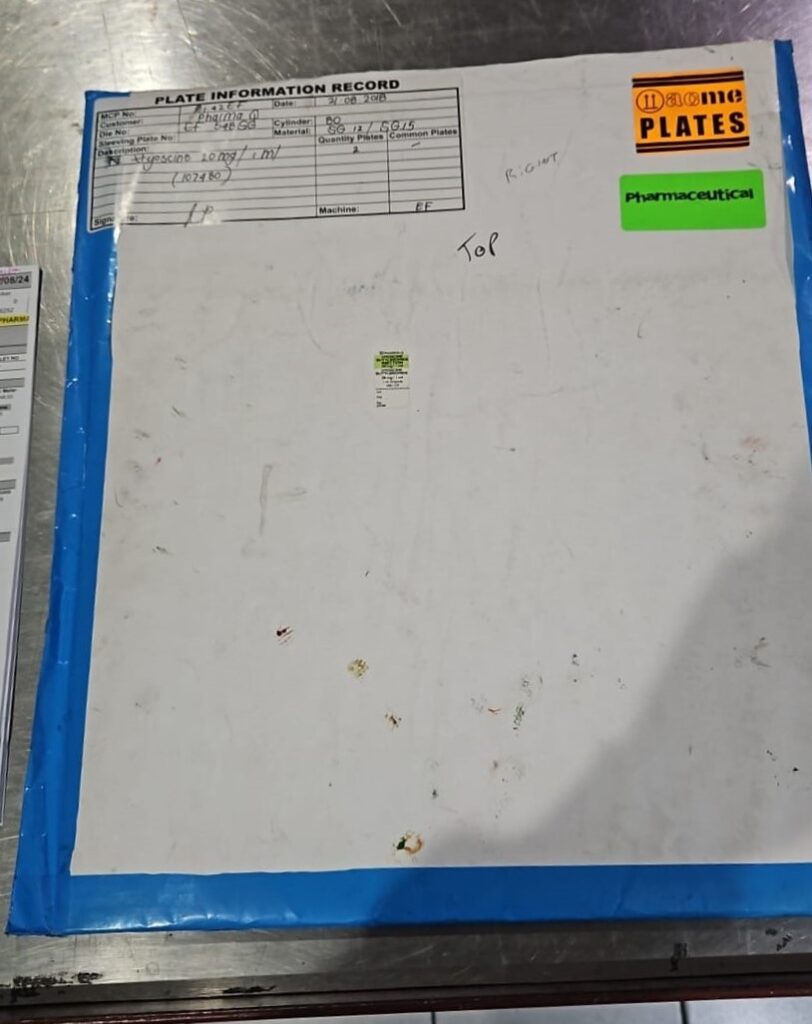

The old method of storing plates consists of a handmade envelope, which was made from a thick carton paper and the use of tape to seal the sides and bottom. The individual that assembled the envelopes and fulfilling a different role withing the company has an average hourly salary of R 130 / Hour, with an average assembly time of 4 min per envelope.

Adding the labour cost and the cost of the material an enveloped cost our customer in a region of R 18.60 to make a single envelope internally.

With about 2400 plates manufactured per year an average of 68 plates or 3% is plates that needs to be replaced due to storage damaged, calculating this value into the cost of an envelope to accommodate for the replacement plate and new envelopes over the amount of plates that is manufactured per year it cost them an average of R 38.44 per envelope.

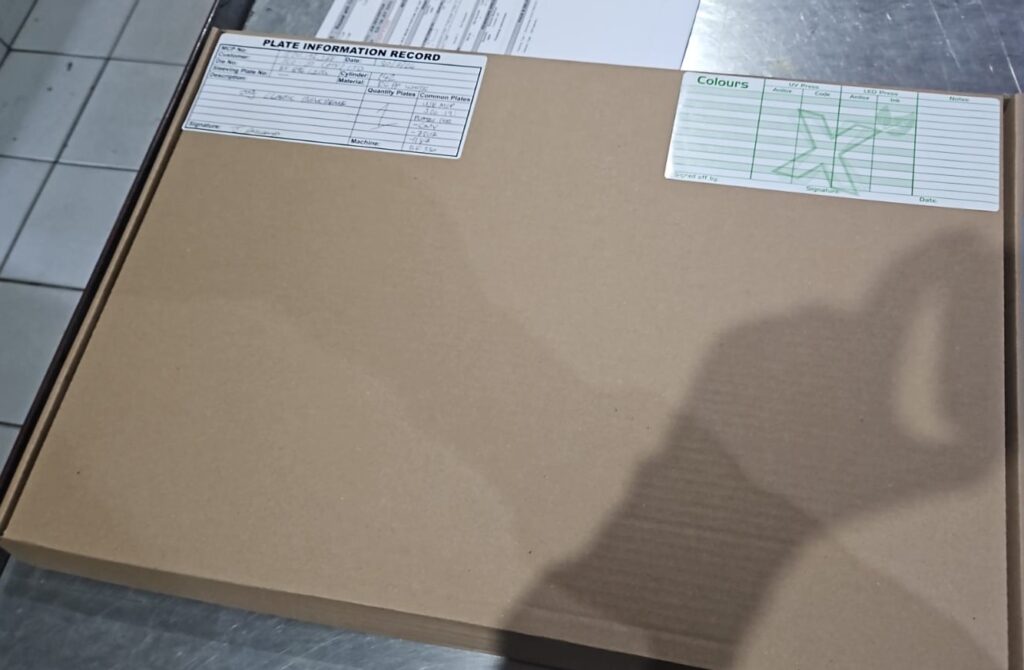

So why call our solution the ultimate solution, lets start at the assembly our design is 88% faster to assemble accounting for about 30 seconds if we compare this to the old method it will take one person a total of 160 hours to assemble one years plates storage compared to 20 hours average for the new design, this allows give the person a total of 140 hours back per year to focus on his primary role within the company.

As everything in life nothing is perfect and we have predicted a 0.2% damage rate in one year this means that a total of 5 plates will need to be replaced, taking all of this into account along with the material cost and labour the new solution cost our customer an average of R 10.83 per unit.

This results in a saving of 355% compared to the old storage system, in addition to a financial side the allows our customer to store the plates easy in order according to the system and allowing for visual management within the storerooms. The plates is concealed from light during storage that was not the case with the old methods.

So in conclusion we call this the ultimate solution for the fact that it saves time, saves money, protect your product in a much better way from all environments and it is also a sustainable product.

Along with our customer we will be monitoring the results to provide more statistics on the performance and out put of this product.